High-voltage wiring systems for Europe

with cabling according to VDA standard

in-Tec Bensheim is an internationally active partner in the consultation, development and production of high-voltage on-board electrical systems for the electric drive of commercial vehicles.

Are you a manufacturer of commercial vehicles in the transport sector, off-highway or on water or in the air? Aside from mass production, for example in the automotive sector, do you want to switch to electric or hybrid drives with fuel cells or convert existing vehicle lines?

The production of safe high-voltage cabling concepts is a challenge that requires a high level of experience. With knowledge and extensive expertise from well over 500 projects across Europe, in-Tec Bensheim helps its partners from industry to develop and produce individual solutions for high-voltage connections. Of course, according to high quality standards such as the VDA.

In-Tec also takes care of the planning and production of the specific high-voltage technology for fuel cell vehicles in the context of the latest technology trends such as fuel cell drives for commercial vehicles.

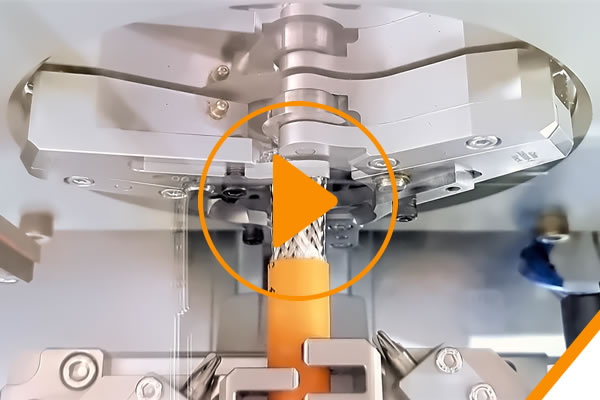

Consulting, development and production of high-voltage cable assemblies. We are specialists in safe high-voltage cabling for the electrification of drives.

Industry expertise for your market

Know-how from over 500 projects

Our services cover various subject areas. We have made a list of selected topics. Find out more about it by clicking the keywords below: High-voltage on-board network, Pigtails, On-board network development, High-voltage plugs, Electric ships, Prototype construction, Electrification of boats and ships, High-voltage power distribution, Stationary energy storage, Electric fruit harvesting vehicles, High voltage for autonomous vehicles, Cable assembly for Bosch drives, Military applications, ...